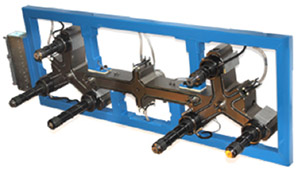

Madison Heights, Mich. – DME Company, a leading provider of mold technologies, recently expanded its comprehensive line of hot runner products and services with the launch of the new Unitized Open Gate Hot Runner System, a high-precision system that comes pre-wired for fast, easy installation.

For customers who don’t need a full hot half system with plates – but still want something with minimal setup time – the DME Unitized Open Gate Hot Runner System is an ideal midway solution that reduces labor in sequential filling and family mold applications.

Other benefits for processors include:

- Improved part quality and part design flexibility

- Elimination of secondary trimming, with zero gate vestige on molded parts

- Minimum flow disturbance and better system reliability, with side-entry nozzle flow channel ensures.

The new unitized system, which is available with front- and rear-loaded nozzle heater options and in “A” dimensions ranging from 52mm to 500mm, joins other unitized systems as part of DME’s industry-leading array of hot runner products that meet customers’ diverse needs. From components to full hot half systems, DME now offers faster delivery at more competitive prices than ever.

“We’re expanding our product lines to accommodate mold makers’ and designers’ needs to cut costs and save time,” said Craig Kovacic, Hot Runner Business Manager. “Our newest addition allows customers to reduce lead times and costs by giving DME responsibility for the system.”

The new unitized system is also good news for customers with multiple international locations because it adds to DME’s growing global product platform – bringing replacement parts, standardization and simplified mold design across all operations by eliminating region-specific design characteristics.

“As a leader in hot runner technology for over 40 years, DME remains committed to supporting customers who just want to build their own hot runner systems out of reliable components,” said Kovacic. “We offer the resources and technical support to help them determine the right components for their application and put them into a workable design.”

|