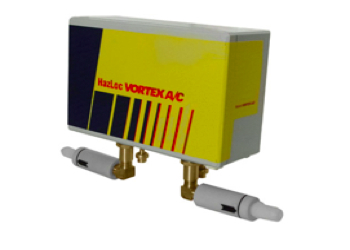

The newest of Vortec’s line of HazLoc enclosure coolers, capable of removing heat at up to 5000 BTU/hour, won official UL certification this month. The Vortec Dual HazLoc Vortex A/C model 7570 is innovative in that it effectively cools even very large enclosures through a unique 2-stage cooling process, while conserving compressed air.

The UL certified Dual HazLoc model 7570 launched on January 18, 2013. “The Dual HazLoc Vortex A/C has higher cooling capabilities than any other HazLoc Vortex A/C model,” stated Vortec Engineering Manager Steve Broerman. “This newly certified product gives facility managers in extremely hot hazardous industrial locations a safe, efficient and cost-effective means of ensuring that hazardous facilities never experience shutdown due to control system or electronics overheating.” With this approval, now all 4 HazLoc Vortex A/C models are certified, providing cooling capacities ranging from 1500 – 5000 BTU/hour.

The newly UL-certified Vortec Dual HazLoc Vortex A/C model 7570 draws on Vortec’s fifty years of air technology expertise and in-depth knowledge of industrial needs to fill the need for safe cooling in Class I Div 2, Class II Div 2 Types F &G, and Class III hazardous locations. Vortec’s experience serving a broad spectrum of industries gives them insight into the challenges faced by facility managers striving to maintain a healthy environment for workers and prevent equipment failure due to overheating.

The Dual HazLoc is one of four HazLoc Vortex A/C models to win approval from the independent safety certification organization Underwriters Laboratory. Vortec made history in late 2012 by becoming the first company ever to gain UL approval for a line of enclosure coolers designed especially for the rigors of hazardous industrial locations. “Prior to Vortec’s development of its line HazLoc Vortex A/C models, industrial facility managers only cooling option was to spend thousands of dollars to modify traditional Freon air conditioning units for hazardous locations,” Broerman stated.

All of Vortec’s HazLoc Vortex A/C units operate in environments up to 175 degrees F. They are designed to cool environments quietly rather than adding to industrial noise with its 62 dBA operation, 78% quieter than typical vortex coolers. The design of the units ensures that no ambient, dirty or humid air enters the cabinet. They require no wiring and can be easily installed in minutes. A mechanical thermostat turns the unit on only when necessary. The enclosure coolers are successfully cooling electrical and electronic cabinets in a wide range of industrial environments from steel mills to food manufacturing. |