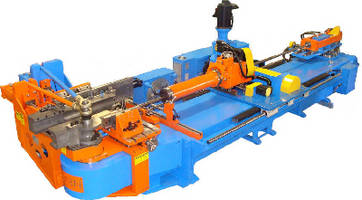

Horn Machine Tools, Inc. introduces the 2010 Elite Series of tube bending machines with capacities ranging from 1-1/4 in. to 10 in. Designed for tube bending in automotive, aviation, HVAC, boiler, shipyard and general fabrication applications, the Elite Series offers a 50-percent reduction in set-up time, user-friendly features, extended service intervals and faster bending speeds.

"We've simplified the design, construction and set-up of our Elite Series tube benders to improve operator interaction with the machine while eliminating features that caused unnecessary wear and hassle," says Kent Horn, president, Horn Machine Tools, Inc. "Tool change time has been reduced by as much as 50 percent, adjustments and positioning are often done now without tools, and a new higher horsepower main drive motor provides faster bending and open/close speeds."

Additional Product Information

2010 Elite Series benders are lowered to a comfortable load height of 36 in. from the floor to the center of the tube (based on a 5-in. bender), although taller machines are available as an option if greater floor clearance is desired. The machines feature a new direct acting swing arm design that reduces clamping deflection, puts clamp force on the center of the tube, and eliminates wear parts, pins, links, plates, and doesn't require a jack screw to adjust tool pressure. A direct acting clamp and PD, along with a new upright PDA design, makes it easy to remove and position tooling, often without tools:

- No tools needed to change or position the clamp die.

- No tools needed to change the pressure die.

- Upgrading the clamp and pressure die slide with linear bearing guides eliminates the aluma-bronze slides and gibs.

- Heavy-duty precision linear bearings provide exact tool positioning and eliminate metal-to-metal wear surfaces.

- Tool holder is easy to move and position; no T-slot slide.

- Clamp position is preset by the length of the bar.

- Linear bearings have load centered to reduce wear.

Pressure is programmed and stored in the control.

Mandrel base improvements include an electric position adjustment that makes it easy to move and reposition without tools, a quick disconnect mandrel rod that is easy to remove and replace without tools, and front- and rear-guided rails that offer higher rigidity and increased service life of the cylinder rod. Similarly, wiper base improvements eliminate the need for tools to adjust the X or Y position and allow for easy adjustment and repeatable set-up position. A positive-locating wiper holder and mounting bar eliminates guesswork when mounting the wiper die. Easy rake angle adjustment and repeatable positioning further reduces set-up time, while X-axis side shift servos and improved tool support further eliminates the need for tools to make adjustments.

The 2010 Elite Series also features a functional, compact design built for speed: a single cabinet for access to machine controls and circuitry, a new larger horsepower main drive motor that increases open/close and bending speeds, and an increased retractable wiper speed thanks to a smaller, optimized cylinder. Faster tool changes reduce overall set-up time up to 50 percent, and fewer components and contact points throughout the machine extends service intervals. |