Pump manufacturer Blue-White Industries has reduced the time required to program custom products substantially by using the feature-recognition capabilities of Delcam’s FeatureCAM feature-based CAM system to largely automate the programming process. In the past, programming parts for custom products took about two days each because programmers had to define and create toolpaths individually for each feature.

"When our engineers modify a part design, FeatureCAM recognises any changes to the geometry automatically and updates the existing toolpaths,” said Darrell Freeman, CNC Coordinator for Blue-White Industries. "This reduces the time required for programming for a new design to an average of fifteen minutes. Even programming packages that are much more expensive cannot do what FeatureCAM can do.”

Founded in 1957, Blue-White Industries is a leading manufacturer of metering pumps, flow-meters and water treatment accessories. One of the keys to the company’s success is building custom-designed products to fit customers’ specific needs on a fast-turnaround basis.

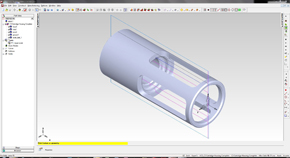

Blue-White Industries produces its pumps in its Huntington Beach, California, manufacturing facility using Mori-Seiki turning centres, and Mori-Seiki, Mazak and Fadal machining centres. The company’s experienced engineers use SolidWorks CAD software to modify the existing product designs quickly to meet customers’ special requirements.

"By the time the custom product is designed, it is typically already very close to the time it needs to be delivered to the customer,” said Mr. Freeman. "The CNC software we used in the past caused major delays because it would not recognise the geometry or features of our SolidWorks models.”

Another problem Mr. Freeman found with the company’s previous programming software was limited technical support. "We sometimes needed to have a custom post-processor written to meet our specific requirements,” he remembered. "We found that our previous CNC programming software supplier was unable to deliver new posts on a timely basis.”

Mr. Freeman reviewed more than ten programming packages before selecting FeatureCAM. "FeatureCAM was very easy to learn,” he said. "The program is so intuitive that I received the software on day one and produced our first CNC code on day two. We stopped using our previous software package and began using FeatureCAM for all of our work on the same day.”

"FeatureCAM has substantially streamlined our programming process,” Mr. Freeman added. "When we modify the geometry of a part that has already been programmed, we simply import the new geometry into FeatureCAM and associate it with the existing part program. The software recognises the features and geometry of the new model automatically and associates them with the existing toolpaths. In most cases, there is no need to change the strategies so we simply check the modified toolpaths to make sure they are correct and run the post to generate the new program. The entire process takes only about fifteen minutes.”

FeatureCAM also provides the ability to evaluate features in new designs and recommend toolpaths automatically. "Nine times out of ten the toolpaths recommended by the software are correct, plus it is easy to edit the remainder to get exactly what we want,” Mr. Freeman said.

"The technical support provided by FeatureCAM is far superior to our previous supplier,” Mr. Freeman added. "For example, if I need a post that provides a special feature, I can send the details to Delcam in the morning and have my new post back in the afternoon.” |