|

| Microsito |

| Profilo aziendale |

| Azienda News |

| Prodotti Show Room |

| Prodotti News |

| Cataloghi e Note Tech |

| Commercio Informazioni Visualizza |

| Web TV |

| Alert di prodotto |

| Internazionale Contatti |

| Informazioni di Contatto | ||

|

| Prodotti in vetrina |

|

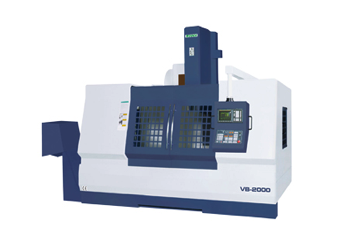

Double Column Machining Center

Briefing:

High Speed Vertical Machining Center

*Saddle suported by 3 pieces of roller linear guides. This design allows an increase of 25% in cutting capacity.

*Y axis slideway mounted on the top of cross rail to shorten the distance from spindle head to Y axis slideway.

*Door width more than 1800mm

*Unique one-piece casting column. Double ribs design. Cutting capacity:: S45C, 25cm3 / KM/min. up X, Yaxis ball screw with oil cooling system. 1 set screw chip conveyor system on each left and right side of bed. This design help to remove the chips out of the base, and avoid the thermal deformation by thermal growth.

Briefing:

High Speed Vertical Machining Center

|

| Categorie di prodotti. | ||||||||||

|

|

||||||||||||||||

Diritti d'autore 2012 Allitwares Corporation Tutti riservati. www.allmetalworking.com è una divisione di Allitwares Corporation |

Torni | Electronic Lathes | Ecoca Industrial Co., Ltd. |